In boiler operation, water quality management is a vital link. The alkalinity and pH value of boiler water are two key indicators to measure water quality, and there is a close connection and mutual influence between them.This paper aims to explore the relationship between boiler water alkalinity and pH and their impact on boiler operating safety and efficiency.Our company provides desktop and online pH and alkalinity water quality testing instruments. If you need detailed information and quotes, please contact customer service directly.

Boiler water alkalinity, also known as boiler scale, is an important parameter to measure the amount of alkaline substances in water.Too high or too low boiler water alkalinity will have an adverse effect on boiler operation.

1.Excessive alkalinity: may cause alkaline corrosion of the boiler, cause foaming in the boiler water, and affect the steam quality. For riveted or expanded boilers, excessive alkalinity may also cause caustic embrittlement, increasing the risk of boiler operation. In addition, high alkalinity will also deteriorate the steam quality and affect the product quality of the steam user.

2.If the alkalinity is too low, the residual hardness in the feed water may cause scale to form, making it difficult for phosphate to react with calcium ions, thereby increasing the corrosiveness of boiler steel.

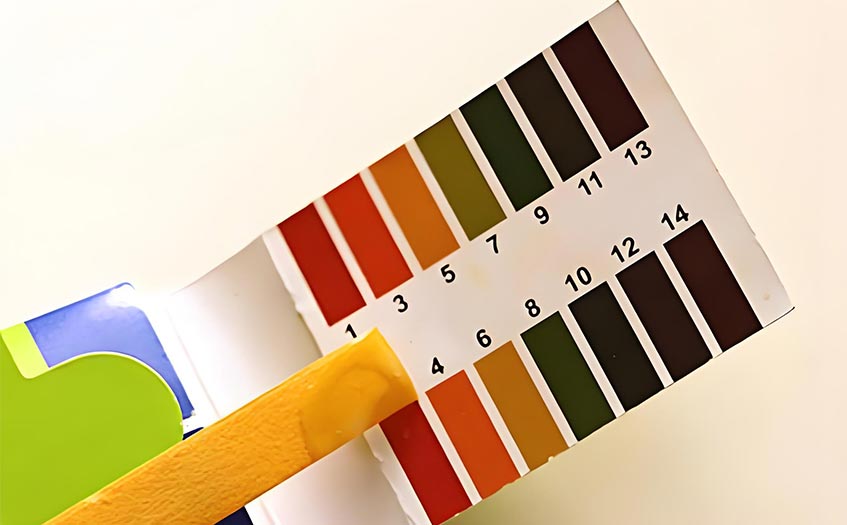

The pH value is an indicator of the acidity and alkalinity of a solution. It directly reflects the content of hydrogen ions (H⁺) or hydroxide ions (OH⁻) in water. The pH value range is 0-14, where 7 is neutral, less than 7 is acidic, and greater than 7 is alkaline. The pH value of boiler water also needs to be maintained within a certain range to ensure the safe operation of the boiler.

Too low pH value: It will increase the corrosiveness of water to boiler steel, affect the reaction between phosphate and calcium ions, and reduce the removal efficiency of water slag. In addition, low pH value will also promote the hydrolysis of silicate, increase the amount of silicate dissolved in steam, and further deteriorate the steam quality.

The pH value is too high: Although it can inhibit the hydrolysis of silicates, a too high pH value often means that there is more free sodium hydroxide in the boiler water, which can easily cause alkaline corrosion.

There is a certain correlation between boiler water alkalinity and pH, but they are not completely equivalent. In the case of the same alkalinity, the pH value in the solution may also be different due to the difference in alkalinity components. Therefore, even if the alkalinity is the same, there may be differences in pH.

The normal pH value range of boiler water is usually between 7-12, depending on the operating conditions of the boiler and the water quality requirements. For boilers using softened water as make-up water, the alkalinity and pH value of the boiler water should be strictly controlled to ensure the safe operation of the boiler and the quality of steam.

Boiler water alkalinity and pH value are important parameters in boiler water quality management, and there is a complex relationship between them. Reasonable control of boiler water alkalinity and pH value is of great significance for reducing boiler corrosion, improving steam quality, and ensuring safe operation of the boiler.Therefore, during boiler operation, the alkalinity and pH value of boiler water should be regularly monitored and adjusted to ensure that they are within the appropriate range. At the same time, attention should also be paid to other aspects of water quality management, such as controlling the hardness and dissolved oxygen in the feed water, in order to comprehensively improve the operating efficiency and safety of the boiler.Our company provides desktop and online pH and alkalinity water quality testing and monitoring instruments. If you need detailed information and quotes, please contact customer service directly.