Chloride ions (Cl⁻) in water directly impact industrial equipment corrosion, drinking water safety, and ecological health. Chinese national standards (e.g., GB/T 11896, HJ 84) specify strict limits for chloride ion concentrations in different scenarios. This article, based on Xi’an erun Environmental Technology’s equipment and case studies, explains chloride ion testing methods, standard values, and real-world applications.

1.1 National Limits by Application

Application | Chloride Ion Limit (mg/L) | Reference Standard |

Drinking Water | ≤250 | GB 5749-2022 (China) |

Industrial Circulating Water | ≤200 | GB/T 50184-2011 (China) |

Metal Corrosion Prevention | ≤25 | GB 50235-2010 (China) |

Environmental Air | ≤50μg/m³ | HJ 84-2023 (China) |

Electronic Component Cleaning | ≤10 | IEC 60068-2-20 (International) |

1.2 International Standards

- US ASTM D4327: Requires detection limit ≤0.001 mg/L.

- EU EN 1413: Limits drinking water chloride to ≤250 mg/L, aligning with Chinese standards.

2. How to Measure Chloride Ion Content?

2.1 Laboratory Methods

Method | Advantages | Limitations | Recommended Equipment |

Silver Nitrate Titration | Simple, low cost | Low precision (卤0.1 mg/L) | ERUN-SP7-11 |

Ion Chromatography | High precision (卤0.001 mg/L) | Expensive, requires expertise | Thermo Scientific ICS-6000 |

Potentiometric Titration | Automated, low error | Requires electrode calibration | Metrohm T50 Titrator |

2.2 Field Rapid Detection

- Portable Ion-Selective Electrode:

- Detection limit: 0.01 mg/L

- Response time: <30 seconds

- Ideal for emergency monitoring and site inspections.

Case Study: A chemical plant used Xi’an ERUN’s ERUN-SP7 portable analyzer to detect chloride ions in circulating water within 15 minutes. Exceeding limits prompted adjustments to softening processes, avoiding equipment corrosion and saving millions in repairs.

3. Risks of Exceeding Chloride Limits & Mitigation Strategies

3.1 Real-World Consequences

- Case 1: Stainless Steel Pipe Corrosion

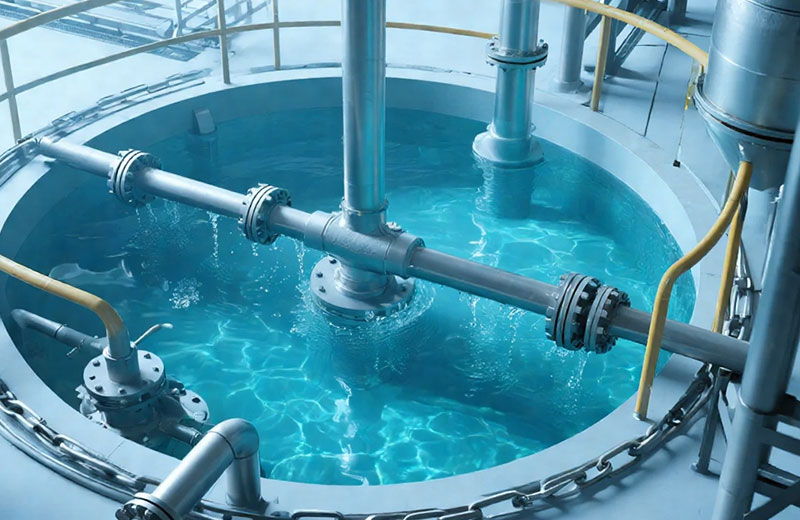

- Background: A power plant’s cooling water reached 300 mg/L chloride, far exceeding GB 50235-2010’s 25 mg/L limit.

- Outcome: Pitting corrosion caused pipe rupture, costing over $200,000 in repairs.

- Case 2: Electronic Component Short Circuits

- Background: A chip manufacturer’s cleaning water had 15 mg/kg chloride residues, increasing electrochemical migration (ECM) failure rates by 30%.

- Solution: Upgraded to a pure water system (PW-100), reducing chloride to 0.001 mg/kg.

3.2 Prevention Strategies

- Process Optimization: Reverse osmosis (RO) + ion exchange removes ≥99% of chlorides (data from Industrial Water Treatment, 2023).

- Real-Time Monitoring: Deploy online sensors (e.g., ERUN-ST7-11) with alert thresholds (90% of standard limits) and corrective action thresholds (120% of standard limits).

4. Xi’an ERUN Environmental Technology: Expertise & Support

4.1 Core Product Recommendations

Product Model | Key Features | Applications |

ERUN-SP7-11 | Portable chloride analyzer, results in 15 mins | Emergency monitoring, field inspections |

ERUN-ST7-11 | Lab-grade multi-parameter analyzer, ≤2% error | Industrial water, drinking water |

ERUN-ST3-J4 | UV spectrophotometer compatible with chloride testing | Environmental air, wastewater |

4.2 Company Credentials

- Certifications: National High-Tech Enterprise, Ce certified lab.

- After-Sales: 24/7 support, engineers on-site within 4 hours.

5. Industry Trends: Smart & Green Solutions

- AI Predictive Models: Forecasts chloride fluctuations 3 days in advance (Smart Water 2025 White Paper).

- Green Testing: erun’s equipment uses non-toxic reagents (e.g., n-hexane instead of carbon tetrachloride), reducing chemical waste by 60%.

- IoT Integration: 4G/5G connectivity uploads data to cloud platforms (compatible with SCADA systems).

Xi’an ERUN Environmental Technology ensures compliance with standards like GB/T 11896 and HJ 84 through solutions ranging from labs to fieldwork. With a detection limit of 0.001 mg/L and ≤2% error rates, their equipment safeguards industries and public health.