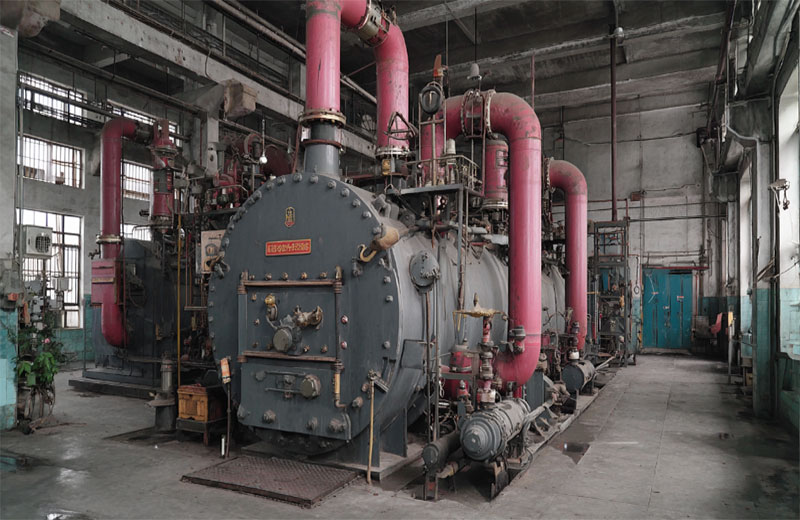

Ever wonder why your biomass boiler’s performance dips or why maintenance costs keep climbing? The answer often lies in water quality. Poor water quality can lead to scaling, corrosion, or even catastrophic boiler failures. According to the China Boiler Water Treatment Association, about 80% of boiler incidents in China stem from substandard water quality, causing annual economic losses averaging $300,000 per enterprise. Scaling alone can reduce heat transfer efficiency by 15-20%, wasting fuel and hiking operational costs. A report from China’s Special Equipment Inspection Institute notes that 68% of boiler accidents are linked to scale buildup.

Imagine running a biomass processing plant and facing unexpected downtime due to water-related issues. That’s not just a repair bill—it’s lost production time. The Ministry of Ecology and Environment emphasizes that proper water quality management cuts industrial wastewater emissions, aligning with China’s carbon neutrality goals. Regular testing with reliable instruments prevents minor issues from snowballing into major headaches, potentially extending boiler life by 10-20 years. Many plants now combine online monitoring with portable devices for real-time insights, ensuring efficiency and safety.

The GB/T 1576-2018 standard, issued by China’s National Market Supervision Administration, is your go-to guide for biomass boiler water quality. Effective since December 2018, it applies to stationary steam and hot water boilers with steam pressures below 3.8MPa, including biomass-fueled systems. It sets strict limits for feedwater, boiler water, steam condensate, and makeup water to prevent corrosion, scaling, and contamination.

Think of this standard as a boiler’s health checklist. For example, feedwater hardness must stay below 0.03 mmol/L, pH between 7.0-9.0, and dissolved oxygen under 0.1 mg/L. Boiler water alkalinity should range from 6-26 mmol/L, with phosphate levels at 5-12 mg/L to combat scaling. Biomass boilers, due to high ash content in fuels like straw or wood, are prone to silicate scaling, making adherence to these limits critical.

Here’s a quick reference table for key indicators (based on GB/T 1576-2018 for boilers ≤1.0MPa):

| Parameter | Feedwater Limit | Boiler Water Limit | Unit |

|---|---|---|---|

| pH | 7.0-9.0 | 10.0-12.0 | - |

| Hardness | ≤0.03 | - | mmol/L |

| Dissolved Oxygen | ≤0.1 | - | mg/L |

| Iron | ≤0.3 | ≤0.3 | mg/L |

| Phosphate | - | 5-12 | mg/L |

| Alkalinity | - | 6-26 | mmol/L |

| Turbidity | ≤5 | - | NTU |

These values, drawn from the standard and government reports, highlight the need for precise monitoring. Ignoring them can slash boiler efficiency by up to 20% and raise safety risks. For biomass boilers, tweak testing based on fuel type—high silicate fuels demand extra attention.

Let’s break down the must-monitor indicators. pH measures water’s acidity or alkalinity. Too low, and you risk metal corrosion; too high, and alkaline scaling kicks in. GB/T 1576-2018 sets boiler water pH at 10-12 to counter biomass fuel’s high ash content. Hardness, driven by calcium and magnesium, is a scaling culprit. The Ministry of Ecology and Environment notes that 1mm of scale increases heat loss by 8%.

Dissolved oxygen acts like a silent saboteur, accelerating corrosion. Keeping it below 0.1 mg/L is non-negotiable. Iron levels signal corrosion, while phosphate and alkalinity prevent scaling and buffer pH swings. In a real-world case, a furniture factory ignored dissolved oxygen testing, leading to pipe perforations and $70,000 in repairs. Weekly testing with multi-parameter instruments can catch these issues early, as these parameters often interplay—high hardness often pairs with alkalinity spikes.

Choosing the right tools makes testing a breeze. Portable devices like pH meters and dissolved oxygen analyzers offer quick results, ideal for on-site checks. Online monitoring systems, perfect for large plants, provide 24/7 data. Common instruments include:

pH Meters: Measure acidity with 0.01-unit precision.

Dissolved Oxygen Analyzers: Monitor oxygen to prevent corrosion.

Turbidity Meters: Detect suspended solids, with a limit of 5 NTU.

Conductivity Meters: Gauge total dissolved solids, reflecting hardness.

Phosphate Analyzers: Track anti-scaling agents.

A study from the Journal of Industrial Engineering shows that advanced instruments reduce boiler failures by 30%. For biomass boilers, multi-parameter devices handle fuel variability best. Brands like Erun Environmental offer reliable options, with some systems integrating mobile apps for instant alerts.

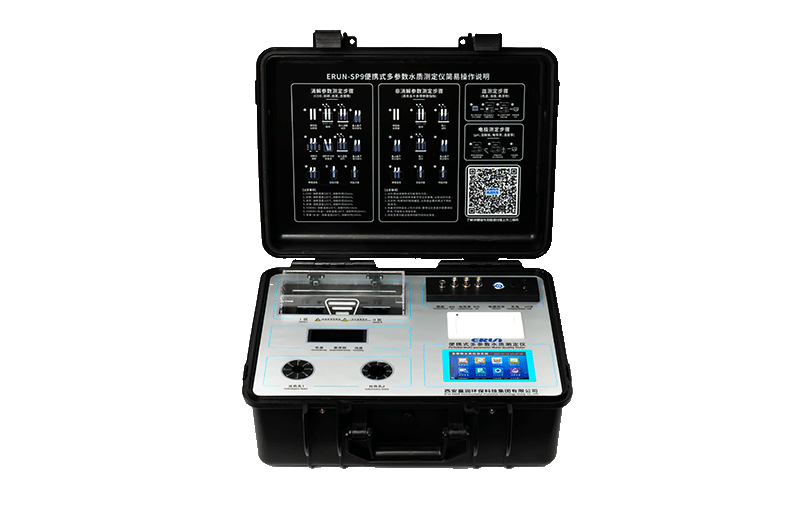

For a standout option, check out the ERUN-SP9-11 Portable Boiler Water Quality Analyzer from Erun Environmental . This device measures pH, conductivity, dissolved oxygen, and more with 0.001 mg/L precision, meeting GB/T 1576-2018 standards. Its lightweight design and long battery life make it perfect for field inspections.

In a food processing plant case, the ERUN-SP9-11 detected hardness exceeding 0.05 mmol/L, prompting timely water softener adjustments that saved $15,000 in potential downtime. Certified by national metrology standards, it’s user-friendly, with data export features for reports. Compared to lab testing, it cuts time by 50% and costs by 30%, making it ideal for small to medium enterprises.

Consider a biomass boiler plant in Shandong. They overlooked chloride levels (limit ≤300 mg/L) and saw pH drop below 9.5, causing corrosion. Unsoftened feedwater pushed hardness to 0.1 mmol/L, cutting efficiency by 15% and burning an extra 5 tons of fuel monthly. After lab tests and online monitoring, they introduced phosphate dosing, stabilized pH at 11, and used portable instruments weekly. Within three months, corrosion dropped 80%, saving $30,000 annually in fuel. This case, reported by China Science Net, underscores the value of proactive testing.

To keep your boiler humming, log weekly tests for key indicators and conduct full checks monthly. Train staff to spot anomalies, and invest in tools like the ERUN-SP9-11 for smart monitoring. The Ministry of Ecology and Environment notes that good water quality cuts emissions by 20%. Long-term, this approach boosts safety, efficiency, and sustainability. Start testing today—your boiler will thank you!