The stable operation of your circulating cooling water system is fundamental to industrial safety and efficiency. Have you struggled with scale, corrosion, or microbial growth? The root cause often lies in water quality. This guide decodes the 8 crucial water parameters per National Standards and recommends efficient, precise testing instruments to simplify your water treatment.

In industry, circulating cooling water is a dynamic biochemical reactor, not just a static pool. Poor water quality causes three major issues: Scaling, Corrosion, and Microbial Slime.

The Cost of Scale: According to the Industrial Water Treatment journal, a 1 mm increase in scale thickness can reduce heat exchange efficiency by 8-10%, increasing energy consumption by over 8%. This translates directly into soaring electricity or steam costs.

The Cost of Corrosion: Corroded metal pipes and equipment lead to shorter lifespans, potential leaks, and safety hazards. The costs for repairs and production downtime are immense.

The Cost of Microbes: Microbial slime clogs pipes and cooling tower fill, reduces flow, and creates a breeding ground for under-deposit corrosion. The resulting biofilm is an "invisible killer" of system efficiency.

Therefore, rigorous water testing isn't an expense; it's a crucial investment in production continuity and profitability.

China's Code for Design of Industrial Recirculating Cooling Water Treatment (GB/T 50050-2017) provides the authoritative framework. Here are the 8 essential parameters you must monitor:

1. pH Value - The "Acidity/Alkalinity Barometer"

Why it Matters: pH directly influences the water's tendency to corrode or form scale. Low pH (acidic) accelerates corrosion, while high pH (alkaline) promotes scaling.

Standard Range: Typically controlled between 6.8 and 9.5, depending on the water treatment program and operating conditions.

Testing Instrument: Professional pH Meter. Choose models with automatic temperature compensation and electrode diagnostics to prevent errors.

2. Conductivity - The Indicator of "Total Dissolved Solids"

Why it Matters: Conductivity directly reflects the total concentration of dissolved salts, making it key for controlling the "Cycle of Concentration." Increasing the cycle of concentration significantly saves water and reduces discharge.

Standard Guidance: Managing conductivity to maintain an optimal cycle of concentration is a fundamental practice in modern water treatment.

Testing Instrument: Conductivity Meter. Online models enable real-time monitoring and can trigger automatic blowdown.

3. Calcium Hardness & Total Alkalinity - The "Partners" in Scale Risk

Why it Matters: Calcium ions (Ca²⁺) and alkalinity (mainly HCO₃⁻) are the primary components of calcium carbonate scale. Monitoring them helps predict scaling potential.

Standard Focus: Parameters like the Langelier Saturation Index (LSI) or Ryznar Stability Index (RSI) are used, which combine these values to assess scaling or corrosion tendency.

Testing Instrument: Traditional chemical titration is still used, but a Multi-Parameter Water Analyzer can integrate relevant electrodes or use reagent methods for rapid testing.

4. Chloride Ions (Cl⁻) - The "Catalyst" for Corrosion

Why it Matters: Chloride ions are highly penetrating and can break down the passive layer on metal surfaces, drastically accelerating localized corrosion (like pitting), especially on stainless steel.

Standard Limit: Strict limits vary by material and treatment program; e.g., for carbon steel systems, it's often limited to 700 mg/L.

Testing Instrument: Chloride Ion Selective Electrode or Benchtop Spectrophotometer. The latter offers high precision for lab analysis.

5. Residual Chlorine - The "Firewall" Against Microbes

Why it Matters: Maintaining a residual concentration after adding oxidizing biocides (like chlorine or sodium hypochlorite) provides continuous suppression of microbial growth.

Standard Recommendation: Residual chlorine in the return line should be maintained between 0.1-0.5 mg/L (as Cl₂).

Testing Instrument: Portable Residual Chlorine Meter (DPD method). It's simple, fast, and perfect for field checks.

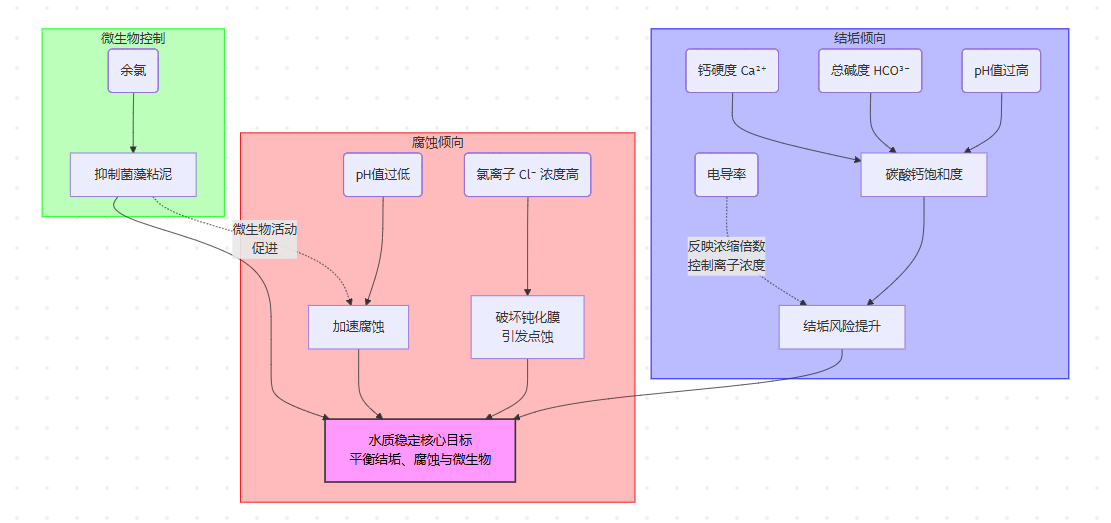

A Visual Guide to the Interconnected Parameters:

(Diagram: pH affects the corrosion/scale balance; Calcium & Alkalinity jointly determine scale risk; Chloride drives corrosion; Residual Chlorine inhibits microbes; Conductivity governs cycle of concentration control.)

Background: A large chemical plant in East China faced persistent scaling in its chiller cooling water system, requiring two high-pressure cleanings yearly and suffering from high energy bills.

Problem Diagnosis: The plant relied on manual daily sampling using outdated test strips and titration kits. Data was lagging and inaccurate, preventing timely adjustment of treatment chemicals, leading to uncontrolled cycles of concentration and severe scaling.

Solution: The plant installed an online monitoring system featuring instruments like the ERUN-SP Multi-Parameter Water Quality Analyzer for real-time tracking of pH, conductivity, and residual chlorine, complemented by precise lab analysis for calcium hardness and chlorides.

Results:

Energy Saved: Stable water quality restored heat exchanger efficiency, saving ~¥380,000 in electricity annually.

Water Saved: The cycle of concentration stabilized at 4.0 (from 2.5), saving ~15,000 tons of water worth ~¥80,000 per year.

Costs Reduced: Avoided two unplanned shutdowns for cleaning, saving ~¥150,000 in maintenance and downtime.

ROI: The instrument investment paid for itself in less than 3 months.

With multiple parameters, choosing the right tool is half the battle. There are three main scenarios:

Laboratory Precision Analysis: Requires high-precision benchtop pH/conductivity meters and spectrophotometers for periodic calibration and definitive analysis.

Field Patrol Testing: Needs robust, portable, and easy-to-use portable multi-parameter water quality testers.

Online Real-Time Monitoring: Requires stable and reliable online water quality sensors and analyzers for process control and automated chemical feed.

For users who need both field patrol and quick lab checks, a versatile Multi-Parameter Water Quality Analyzer is a cost-effective choice. For instance, the ERUN-SP7 Multi-Parameter Water Quality Analyzer is such an instrument. It integrates sensors for pH, conductivity, dissolved oxygen, turbidity, residual chlorine, and more, serving both for multi-point field inspections and precise lab use. This versatility greatly improves efficiency and data consistency.

Managing circulating cooling water is a science, not just an art. Guided by National Standards and driven by accurate data, with a reliable partner like the ERUN-SP7 Multi-Parameter Analyzer, you can shift from reactive fixing to proactive prevention. This ensures your system runs safely, stably, and efficiently, delivering tangible energy savings and intangible security for your operation.