In today industrial environmental monitoring field, it is particularly important to accurately and quickly determine the oil content in water, soil and other media.As an instrument specially used for such detection tasks, the infrared oil tester has been widely used due to its efficient detection capability and accuracy. This article will deeply explore the working principle of the infrared oil tester and reveal its core value in the modern environmental protection and industrial fields.

Infrared oil analyzers work mainly based on the absorption characteristics of substances to infrared light of specific wavelengths. Specifically, different types of organic molecules have different infrared absorption peaks. In the infrared spectrum, oil-containing organic substances such as alkyl and aromatic hydrocarbons will show strong absorption characteristics in certain specific bands. Using this principle, infrared oil analyzers can identify and quantify the petroleum components in the sample.

The instrument usually consists of an infrared light source, a sample chamber, and a detector. During operation, the sample to be tested is first introduced into the sample chamber, and the infrared light emitted by the light source passes through the sample and is received by the detector. The oil components in the sample chamber absorb light of specific wavelengths, causing the intensity of the light reaching the detector to decrease. By comparing the original light intensity with the light intensity after passing through the sample, the instrument can calculate the amount of oil in the sample.

The advantage of this detection method is its accuracy and specificity. Since it directly measures the infrared absorption characteristics of petroleum substances, the infrared oil analyzer can accurately identify and quantify petroleum pollutants in complex environmental matrices, thus avoiding the cross-interference problems that may occur in conventional chemical analysis.

Infrared oil measuring instruments have a wide range of applications, including environmental monitoring, oil field development, marine research, sewage treatment and other fields. In terms of environmental protection, infrared oil measuring instruments can quickly detect water pollution incidents and provide a scientific basis for pollution prevention and control. In industrial production, by monitoring the oil content in wastewater, enterprises can effectively control pollutant emissions and comply with environmental protection regulations.

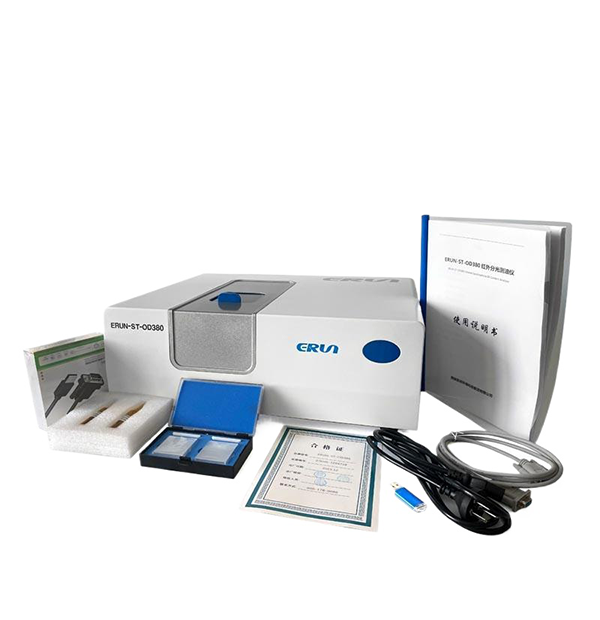

The ERUN-ST-OD380 desktop infrared oil tester (water quality tester) produced by Erun Environmental Protection is easy and quick to operate, with a user-friendly operation interface. Based on infrared spectroscopy technology, it is widely used to measure the content of oil, petroleum, animal and plant oils in water. This not only greatly improves work efficiency, but also reduces errors caused by human operating errors. If you need specific information and quotes for the instrument, you can directly consult the website customer service or call the contact number.

With the continuous advancement of technology, the performance of infrared oil testers is continuously improving, such as lower detection limits, wider measurement ranges, and enhanced data processing capabilities. In the future, with the increasing requirements for environmental protection and the deepening of industrial production automation, the application prospects of infrared oil testers will be broader.

With its unique working principle and advantages, infrared oil tester plays an irreplaceable role in the field of oil pollution monitoring. Its accuracy, specificity and wide range of applications make it an important tool for modern environmental protection and industrial monitoring. With the advancement of technology and the expansion of application fields, the importance of infrared oil tester will be further enhanced, contributing to protecting the environment and promoting sustainable development.

The infrared oil tester is not only a high-precision detection tool, but also a powerful environmental monitoring tool. In the future, its application and development will inevitably become more extensive and in-depth, providing more solid technical support for our environmental monitoring and resource management.