Boilers are an indispensable and important equipment in modern industrial production. Their normal operation is closely related to the water quality. In order to ensure the safe operation of the boiler, extend its service life and improve economic benefits, regular testing of boiler water quality is particularly important. This article will introduce in detail the instruments required for testing boiler water and their importance.

1.Turbidimeter: used to measure the turbidity of boiler water, reflecting the content of suspended matter in the water. If the content of suspended matter is too high, it is easy to form scale inside the boiler, affecting the heat transfer efficiency.

2.Dissolved oxygen meter: used to measure the dissolved oxygen content in boiler water. Dissolved oxygen is one of the main factors causing boiler metal corrosion and needs to be controlled within a certain range (generally less than 0.1 mg/L).

3.Oil tester: detects whether there are oil impurities in the boiler water. Oil impurities will affect the heat transfer efficiency and safe operation of the boiler.

4.TDS meter: Total dissolved solids (TDS) meter is used to measure the total amount of dissolved solids in boiler water, reflecting the purity of water quality.

5.Phosphate Tester: used to measure the phosphate content in boiler water. Phosphate is usually added to boiler water as a corrosion inhibitor to prevent corrosion.

6.Chloride meter: used to detect the chloride content in boiler water. High chloride content will accelerate the corrosion process of the boiler.

7.Alkalinity meter: Measuring the alkalinity of boiler water is one of the important indicators for controlling boiler water quality. Appropriate alkalinity can prevent boiler scaling and corrosion.

8.Sulfite analyzer: detects the sulfite content in boiler water to ensure that the water quality meets safety standards.

All of the above instruments are sold by our company. If you need detailed information and quotations, you can contact customer service directly. We can also provide water quality testing technical solutions.

Boiler water quality testing is a key link to ensure the safe and economical operation of the boiler. During the operation of the boiler, water comes into direct contact with metal materials. If the water quality is poor, the following problems will occur:

1.Scaling and corrosion: dissolved oxygen, alkaline substances, salts and other components in water can cause scaling and corrosion. Scaling can reduce the heat transfer efficiency of the boiler, increase energy consumption, and may cause thermal stress, vibration and other problems, affecting the safe operation of the boiler. Corrosion can damage the metal materials of the boiler, causing leakage or even explosion.

2.Reduced thermal efficiency: Scale and suspended matter will adhere to the inner wall of the boiler, hindering heat transfer and resulting in reduced thermal efficiency. This will not only increase fuel consumption, but may also shorten the service life of the boiler.

3.Environmental issues: Poor water quality will also affect boiler exhaust emissions and increase the risk of air and water pollution.

Boiler water testing is mainly divided into two parts: feed water quality testing and boiler water quality testing. The specific steps are as follows:

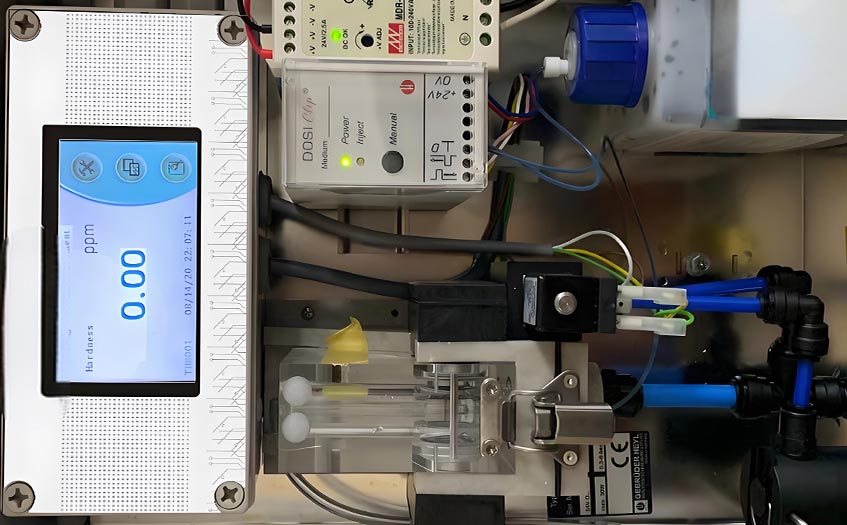

1.Water quality measurement: mainly measuring turbidity, hardness, pH value, dissolved oxygen, oil, total iron, conductivity, total alkalinity, phenolphthalein alkalinity, phosphate, sulfite and other indicators.

2.Boiler water quality determination: mainly determines total alkalinity, phenolphthalein alkalinity, pH value, soluble solids, phosphate, sulfite, relative alkalinity and other indicators.

By measuring these indicators, we can fully understand the quality of boiler water and take appropriate water treatment measures based on the test results to ensure the safe operation of the boiler.

Boiler water quality testing is an important guarantee for the safe and economical operation of boilers. By equipping with professional testing instruments and conducting tests in strict accordance with relevant standards and specifications, we can timely understand the quality of boiler water, take appropriate water treatment measures, prevent the formation of scale and corrosion, improve the heat transfer efficiency and service life of the boiler, and ensure the normal progress of industrial production. Therefore, we should attach great importance to boiler water quality testing, and continuously improve the professional skills and comprehensive quality of test personnel to provide strong guarantees for the safe and economical operation of boilers.